The machining of carbon or carbon fibers has become a popular method for producing highly durable, resilient, and strong components that have an exceptional strength to weight ratio. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

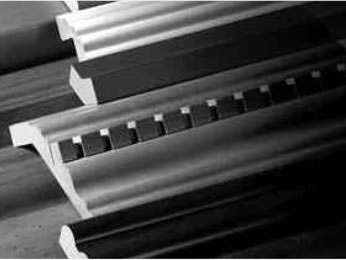

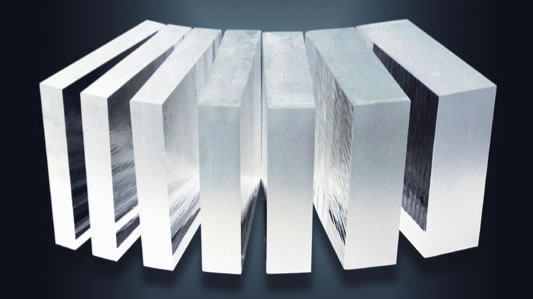

At Amsted, we specialize in precision graphite machining, delivering advanced solutions that meet the exacting standards of modern industries. Our team brings together decades of expertise and state-of-the-art technology to produce high-performance graphite components with superior accuracy, consistency, and surface quality.

SGL Carbon Group is the world's largest manufacturer of carbon and graphite, a leading provider of graphite specialties and the only company in the world to master all related manufacturing processes. We serve many industries with graphite materials, system solutions and graphite design.

More Carbon Machining Companies

Carbon fiber is a composite material that is composed of the precursors of polyacrylonitrile (PAN), pitch, or rayon that are combined with carbon atoms. The filaments of carbon atoms are bonded into a crystalline structure that makes the resulting material stiff and light with resistance to high temperatures and having high tensile strength to be used as supportive material.

The resilience and strength of carbon fiber make it difficult to machine, requiring the use of special tools that have comparable hardness. In many cases, carbon fiber is machined using computer numerical control (CNC) machines that precision drill and shape the raw carbon fiber layers. During the machining process, great care is given to avoid damaging carbon fiber layers and creating carbon fiber components.

Uses for Carbon Fiber

The durability and lightweight of carbon fiber material has made it a highly desirable material that is used by several industries. The extraordinary mechanical performance, thermal conductivity, and low thermal expansion coefficient of carbon fiber makes it an ideal material for a wide array of industrial applications. In all cases, the strength of carbon fiber layers and their lightweight are the main reasons for its usage.

-

Aerospace

An important factor for every aerospace design is weight. Steel, stainless steel, bronze, copper, or any other form of metal is carefully chosen in accordance with its weight. In addition, formability, high strength, and durability are crucial to ensure aircraft and space vehicles can endure the pressure and stress created by air travel. All of the above are reasons that machined carbon fibers are so widely used by the aerospace industry.

The aerospace industry was the first industry to make use of carbon fiber. During the Second World War, certain materials for aerospace production were unavailable and had to be substituted with materials that were readily available. It was during that time that engineers found the value of carbon fibers. In many cases, carbon fiber is preferred over metals because of the material's exceptional strength to weight ratio and longevity, critical aspects of aircraft manufacturing.

-

Automotive

Over the one hundred years since the production of the first commercially introduced automobile, there have been significant demands placed on engineers to produce auto bodies that are lightweight and strong. Carbon fiber has risen to meet the demand and has outperformed all other forms of materials. As a versatile and formable material, carbon fiber has found extensive use in the auto industry. It meets the requirements of strength, durability, longevity, and resistance to high temperatures.

The results of the use of carbon fibers are high-quality, high-performance automobiles that are faster and safer. Carbon fibers are used to manufacture automobile frames and a wide range of internal components, such as hoses and linings. The use of carbon fibers gives designers a wide range of capabilities and enables them to remove heavy metal parts as components of their designs.

-

Electronics

The electronics industry values carbon fiber for its increased natural frequency and how it maintains its dimensional tolerance better than metals and plastics. The thermal coefficient of carbon fiber is equal to the highest thermal coefficient alloy, invar, a nickel iron alloy, which has an exceptionally low thermal coefficient. This property of carbon fiber reduces thermal concerns for sensors, sensitive electronics, and lasers.

The wide use of carbon fiber for electronic applications is due to its excellent electrical conductivity and its non-magnetic properties, essential factors for electrical components. An important usage of carbon fiber in the electronics industry is in electric shielding devices due to carbon fiber’s ability to absorb electromagnetic waves.

-

Recreational Use

Sporting goods made of carbon fiber are more expensive than ones made of other materials. Carbon fiber sporting goods are chosen for their lightweight, durability, and strength, which enhances athletic performance and increases speed. Tennis rackets, golf clubs, softball bats, hockey sticks, and bows and arrows are high quality sporting goods that are manufactured using carbon fibers. The use of carbon fiber gives athletes a competitive advantage.

-

Wind Turbine Blades

The continuing search for renewable energy has led to an increase in the manufacture of wind turbines, which produce electric current by the rotation of their massive blades that are over 150 feet in length. The material that makes up most turbine blades is fiberglass, due to its lightweight and formability. To enable fiberglass blades to last, they require a support material to increase their strength and durability. In most cases, carbon fibers are used.

As thick as a few inches, carbon fibers are used to stiffen fiberglass blades without the addition of weight, which is an important factor for wind turbines. Keeping turbine blades light enhances their performance and makes them more efficient. The increased rate of rotation created by the addition of carbon fiber stiffening enables wind turbines to generate more electricity.

-

Medicine

There are multiple areas where the strength and endurance of carbon fiber is required in the medical field. This is especially true in regard to prosthetics, which is the specialty that makes the most significant use of carbon fiber. As with other industries, the lightweight and durability of carbon fiber make it ideal for the manufacture of replacements for missing body parts or the improvement of the performance of a body part.

In the field of prosthetics, carbon fibers are used to manufacture replacements for limbs, organs, and to improve overall body appearance. The most common use of carbon fiber is in the construction of prosthetics for replacement of amputated limbs, which is very evident in the Special Olympics.

Included in the list of medical uses for carbon fiber are spinal implants and orthopedic implants, due to carbon fiber's strength and durability. A basic consideration for all forms of implants is their ability to withstand the pressure and weight placed on them by the human body. Each of these factors is the reason that carbon fiber is highly valued as part of replacements. Aside from implants, carbon fiber is used with radiation therapy as a protective material. Medical carts and surgical tools are made of carbon fiber to reduce the weight of those instruments.

The many properties of carbon fiber are comparable to those of steel. Although it is as strong as steel, it has the weight of plastics, which makes it ideal for high stress applications with limited space. Its superior strength to weight and stiffness to weight ratios are much higher than either steel or plastics. Since its introduction in the latter part of the first industrial revolution and its use as light bulb filament material, the uses and characteristics of carbon fiber have been explored to the point that new uses are constantly being introduced.

Every year, the market for carbon fiber is expected to increase. Much of this is due to the aerospace and military product industries. The rapid increase in the popularity of carbon fibers is due to its many varieties, which are differentiated by their number of fibers, filament shape, the different strengths of the material, and the fiber’s surface finish. The type of carbon fibers used for an application is determined by the application and its requirements. Although modulus or stiffness may be important for an application, other factors may take precedence.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

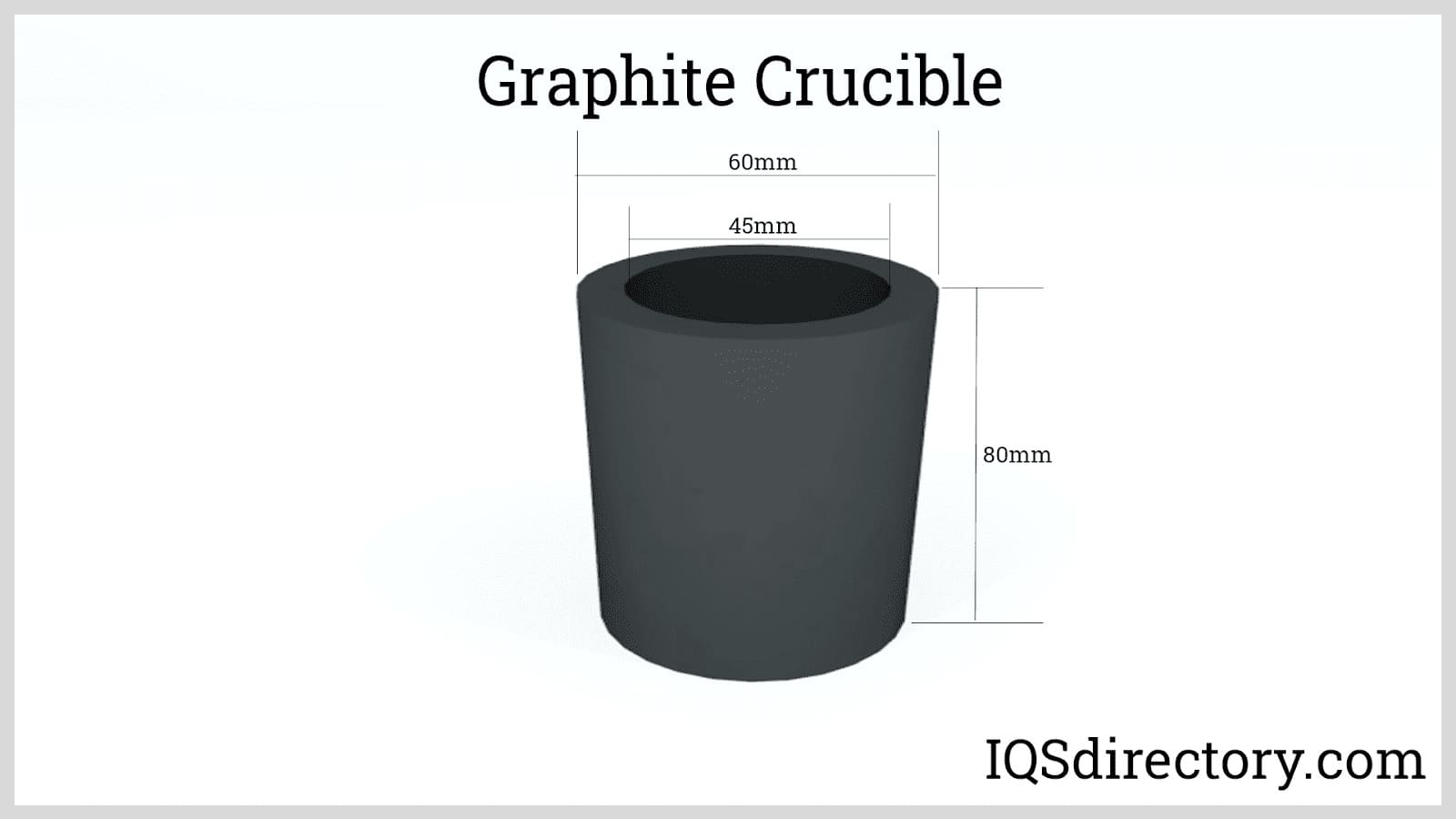

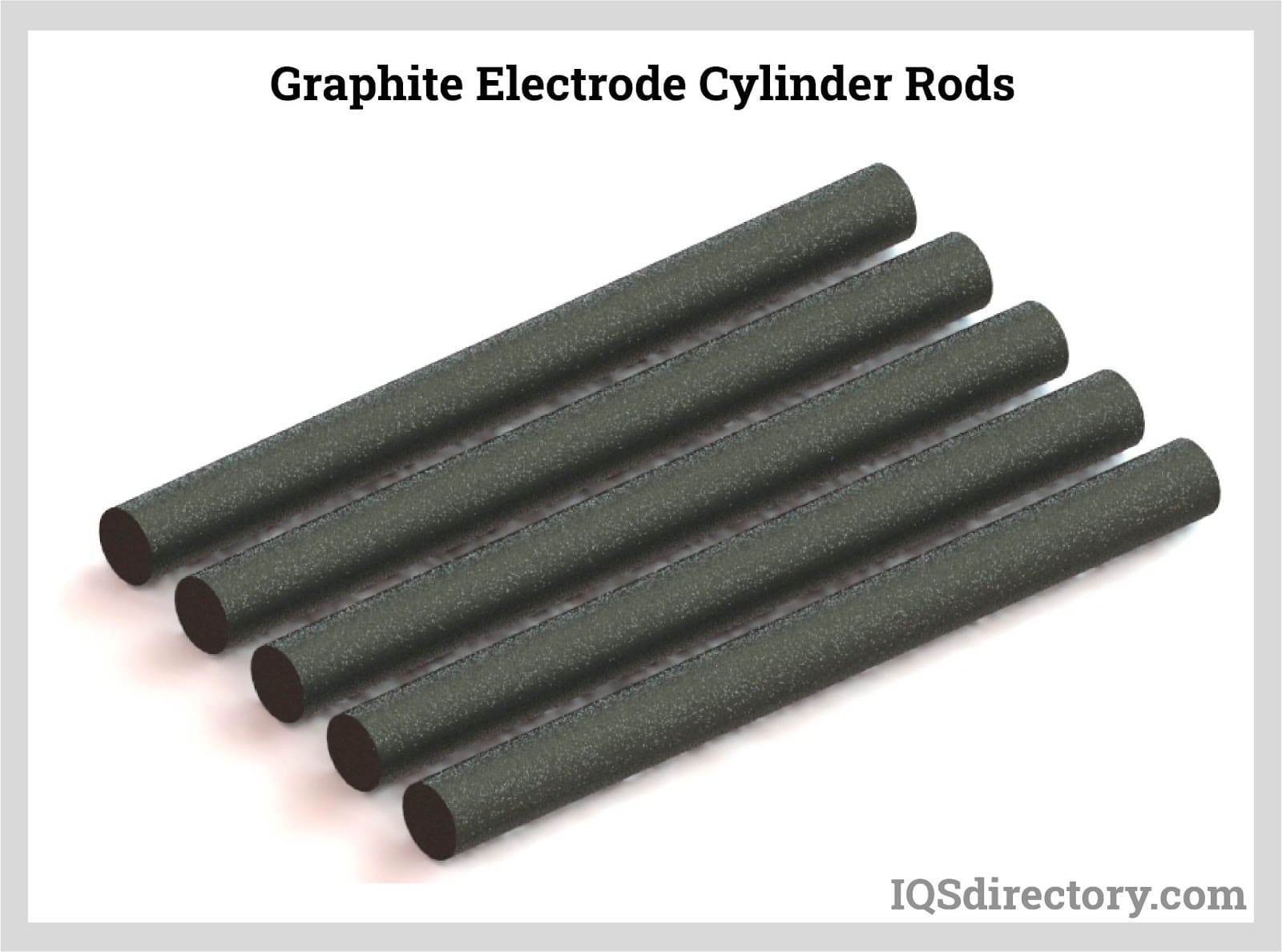

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services