Graphite is known as the most stable form of carbon that is found under standard conditions and because of this it can be found in a series of different types of applications from brake linings and pencils to use in steelmaking and electric motor brushes. A graphite block is a solid shape of graphite, graphitized graphite electrode, or graphite powder isostatic pressing made from artificial graphite, and then machined into various graphite molds. Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

At Amsted, we specialize in precision graphite machining, delivering advanced solutions that meet the exacting standards of modern industries. Our team brings together decades of expertise and state-of-the-art technology to produce high-performance graphite components with superior accuracy, consistency, and surface quality.

SGL Carbon Group is the world's largest manufacturer of carbon and graphite, a leading provider of graphite specialties and the only company in the world to master all related manufacturing processes. We serve many industries with graphite materials, system solutions and graphite design.

More Graphite Block Companies

Carbon exists in its crystalline form as graphite, a naturally occurring allotrope of carbon renowned for its unique properties and industrial versatility. Graphite is composed of layered graphene sheets, granting it remarkable thermal and chemical stability. Under standard conditions, graphite represents the most stable form of carbon, found abundantly in nature and produced synthetically for a wide range of applications. Notably, graphite can transform into diamond under extreme pressure and temperature, further emphasizing its importance in materials science and advanced engineering.

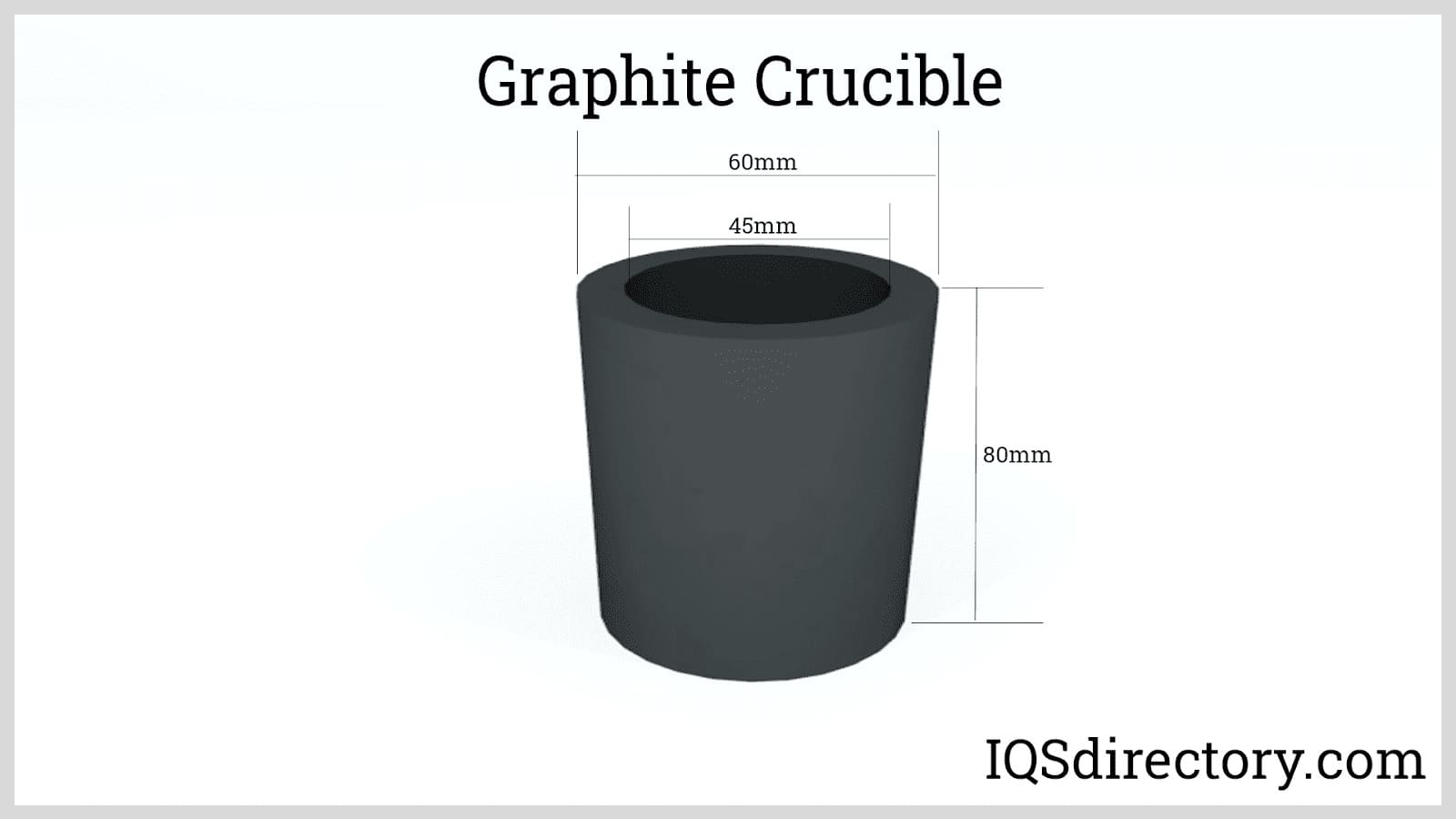

Both natural and synthetic graphite have critical roles in various industries, including as core materials in pencils, lubricants, batteries, electrodes, refractories, and advanced composite materials. Graphite's layered structure imparts lubricity, making it a popular solid lubricant, while its relative chemical inertness and heat resistance drive demand in high-temperature and corrosive environments. The material is often produced as graphite powder—derived from isostatic pressing of synthetic graphite or graphitized electrode—and shaped into a variety of graphite molds or blocks. Both earthy graphite powder and scale graphite are widely used, as are small graphite blocks, often found as carbon brushes in electrical motors. These varied forms highlight the adaptability of graphite across diverse industrial applications and energy storage solutions.

How Graphite is Extracted: Mining Methods and Global Production

Graphite's distinctive hexagonal crystalline structure defines its physical and chemical properties. Extraction of graphite ore is performed using both open pit and underground mining techniques, determined by ore depth, geology, and deposit quality. The largest producers of natural graphite include China, India, and the United States, with emerging markets in Africa and South America contributing to growing global supply. Understanding how graphite is sourced is crucial for buyers seeking reliable, high-quality graphite products for manufacturing, metallurgy, or energy storage.

Interested in the origins of graphite used in industry? Explore questions such as: Where is graphite mined? What are the environmental impacts of graphite mining? How do extraction methods affect graphite quality?

The geology, extraction method, and purification process influence the flake size, purity, and crystal structure of the graphite, which in turn determines its suitability for various applications—ranging from refractory coatings, pencil leads, lithium-ion battery anodes, powder metallurgy, foundry facings, and advanced lubricants. Natural graphite is generally classified into three major types: flake (or microcrystalline), macrocrystalline, and vein (lump) graphite. Each type is found in different geological settings, resulting in unique properties and performance characteristics. Flake and macrocrystalline graphite are typically extracted via open pit or underground mining, while vein graphite—known for its exceptional purity—is mined exclusively underground, notably in Sri Lanka.

Open Pit Mining of Graphite

Open pit mining is suitable when graphite ore is located near the earth's surface, beneath a relatively thin overburden layer. This surface mining method involves removing the overburden, followed by drilling, blasting, and excavating the exposed ore. Quarrying—a specialized form of surface mining—extracts graphite by drilling holes or using explosives, then splitting the rock via water or compressed air. Bore-hole mining is also common, involving the creation of a slurry that is pumped to the surface for further processing.

After extraction, hard rock ore undergoes drilling and blasting to liberate large graphite flakes, which are then crushed, screened, and processed. The graphite is separated by flotation, a process that enhances purity and isolates high-value flakes. Transportation of processed graphite to the surface or to processing facilities is typically conducted using locomotives, conveyor belts, or, in less developed regions, manual tools such as picks and shovels. This method produces significant quantities of high-purity graphite, suitable for use in batteries, refractories, and lubricants.

Underground Mining Techniques for Deep Graphite Deposits

When graphite ore resides at greater depths, underground mining becomes necessary. Several underground techniques are deployed, including drift mining, hard rock mining, shaft mining, and slope mining. Shaft mining, in particular, is essential for accessing the deepest ore reserves, utilizing vertical or inclined tunnels for personnel, equipment, and ventilation. Slope mining employs angled shafts for ore bodies that occur parallel to the earth’s surface, while drift mining, common in mountainous regions of the eastern United States, involves horizontal tunnels excavated below mineral veins.

Efficient underground mining ensures continuous supply of high-quality graphite for demanding applications in metallurgy, electronics, and energy storage. Proper ventilation and ore transportation systems are vital for safety and productivity, particularly as global demand for battery-grade graphite continues to rise due to the electrification of transportation and renewable energy solutions.

How Graphite Blocks are Made: Manufacturing Processes and Quality Control

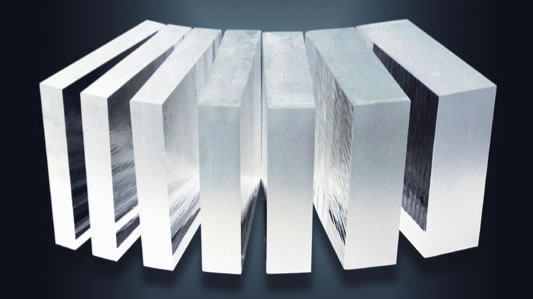

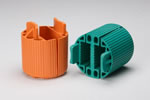

The manufacture of graphite blocks, also known as molded graphite or isostatic graphite, involves several advanced processes designed to produce high-density, high-purity blocks for industrial use. The most prevalent production methods include molding, extrusion, and isostatic pressing, each optimized for specific end-use requirements in fields like metallurgy, chemical processing, and electronics.

Looking to understand the graphite block manufacturing process? Search for: How are graphite blocks manufactured? What is isostatic pressing? How does block quality affect performance in furnaces and EDM applications?

The production process comprises several key stages:

- Crushing and Grinding: Raw carbon materials, such as petroleum coke and pitch, are finely ground to create a uniform starting material.

- Mixing and Kneading: Ground materials are mixed with binders and additives to achieve the desired consistency and chemical composition.

- Screening: The mixture is screened to remove impurities and ensure particle size uniformity.

- Forming/Pressing: Depending on the desired block geometry, molding, extrusion, or isostatic pressing is used to form green (unfired) graphite blocks.

- Roasting: Formed blocks are subjected to high temperatures in an inert atmosphere to carbonize the binder and enhance structural integrity.

- Impregnation: Roasted blocks may be impregnated with pitch or resin to fill pores and increase density.

- Graphitization: The blocks are heated to temperatures above 2500°C to convert carbon to crystalline graphite, optimizing conductivity and purity.

- Machining and Testing: Finished blocks are precisely machined to required tolerances and tested for density, strength, and purity.

Types of Graphite Blocks: Which Is Right for Your Application?

Choosing the right type of graphite block is essential for optimal performance in your specific application. Explore these common graphite block types and their advantages:

Pyrolytic Graphite Block

Pyrolytic graphite blocks are produced from high-purity graphite components subjected to chemical vapor deposition (CVD) in a vacuum furnace. Nitrogen and methane gases are introduced at elevated temperatures, resulting in a high-purity, highly anisotropic graphite with exceptional oxidation resistance. Pyrolytic graphite is prized for its high density, low porosity, and superior performance in semiconductor manufacturing, vacuum furnaces, and aerospace components.

Amorphous Graphite Blocks

Amorphous graphite blocks originate from microcrystalline graphite formed via contact metamorphism between metamorphic agents and anthracite coal seams. These blocks contain higher ash content than other graphite types, making them suitable for applications where cost-effectiveness and moderate purity are priorities, such as foundry facings, lubricants, and brake linings.

Flake Graphite Blocks

Flake graphite blocks are derived from natural flake graphite, formed under high pressure and temperature conditions in metamorphic rocks. Flake graphite boasts excellent electrical conductivity, lubricity, and thermal stability, making it ideal for battery anodes, lubricants, gaskets, and advanced refractories.

Crystalline Vein Graphite Blocks

Crystalline vein graphite blocks, extracted primarily from Sri Lankan deposits, are considered the purest natural graphite, with graphitic carbon content ranging from 94% to 99%. These blocks show superior electrical and thermal conductivity, chemical stability, and machinability, making them highly sought after for batteries, high-performance lubricants, and advanced electronic applications.

Synthetic Graphite Blocks

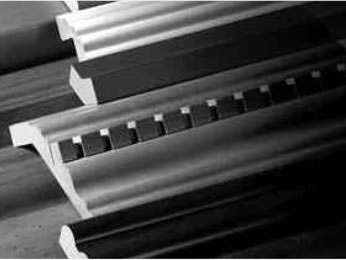

Synthetic graphite blocks are manufactured from petroleum coke and pitch under controlled conditions. These blocks exhibit higher purity and consistency compared to natural graphite, making them suitable for demanding applications such as electric arc furnace electrodes, nuclear reactors, and precision EDM machining. Types include electrographite, used for electrodes, and synthetic graphite, employed in high-temperature furnaces and specialty chemicals.

Why Choose Graphite Blocks? Key Advantages for Industrial Buyers

Graphite blocks, or carbon blocks, are engineered using activated carbon granules and specialized binders, resulting in a rigid structure optimized for filtration, chemical processing, and high-temperature applications. In water filtration, for instance, carbon blocks outperform granular activated carbon (GAC) by immobilizing carbon particles to ensure uniform pore structure, consistent performance, and minimized channeling. This design drives water through the static pores of the block, maximizing contact with the filter medium and enhancing contaminant removal.

Are you evaluating filtration media for water treatment or industrial processes? Search for: What are the benefits of carbon block filters? How do carbon blocks compare to GAC? Which industries use graphite blocks for filtration and purification?

Key advantages of graphite blocks include:

- Consistent Pore Structure: Enables superior adsorption of contaminants and prolonged filter life.

- High Contaminant Reduction: Effectively removes a wide spectrum of impurities, including chlorine, organic compounds, and heavy metals.

- Compact and Versatile Design: Allows integration into diverse product designs, from residential water filters to industrial purification systems.

- Cost-Effective: Offers high performance at a relatively low cost, with renewable carbon sources available for sustainable manufacturing.

- Resistance to Bacterial Growth: Inhibits microbial colonization, supporting longer service intervals and improved health outcomes.

Graphite blocks are also valued for their high thermal conductivity, low thermal expansion, and chemical inertness, making them ideal for furnace linings, heat exchangers, and metallurgical electrodes. Their machinability enables custom shapes and precise tolerances, essential for advanced manufacturing and energy systems.

Applications of Graphite Blocks: From Metallurgy to Energy Storage

Graphite blocks are integral to a wide array of industries due to their unique combination of electrical conductivity, thermal stability, and chemical resistance. The following are some of the most common and emerging applications:

- Furnace Linings and Refractory Materials: Graphite blocks withstand extreme temperatures, making them indispensable in electric arc furnaces, silicon carbide furnaces, and metallurgical reactors.

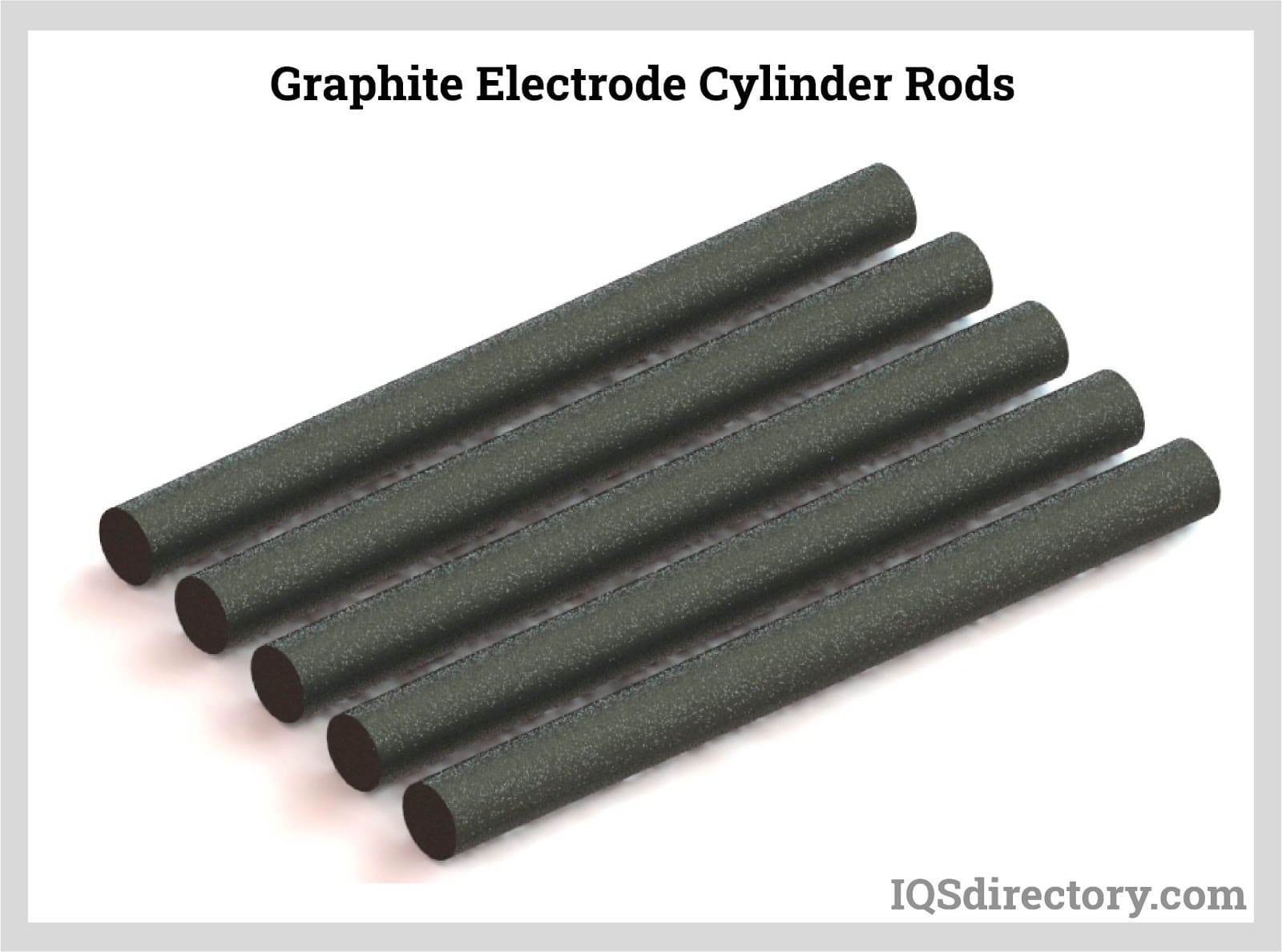

- Electrodes for Metal Processing: Graphite electrodes are essential for arc melting, smelting, and electrolysis processes in steel and aluminum production. Their high conductivity and thermal resistance ensure efficient energy transfer and reduced wear.

- Heat Exchangers and Chemical Processing: Impermeable graphite blocks are used in corrosive chemical environments for heat exchangers, reaction vessels, and process piping.

- Energy Storage and Batteries: As demand for lithium-ion and sodium-ion batteries grows, high-purity graphite blocks and powders are critical for anode material, supporting electric vehicles, grid storage, and portable electronics.

- Hot-Pressing Molds and Continuous Casting: In metal forming and foundry operations, graphite molds and nozzles enable precise shaping and cooling of molten materials.

- Electrical Brushes and Current Collectors: Graphite blocks and plates serve as collecting shoes and brushes for electric trains and electric motors, capitalizing on graphite's low friction and stable conductivity.

- Nuclear Applications: Polycrystalline graphite blocks are used as neutron moderators and reflectors in high-temperature gas-cooled reactors due to their low neutron absorption cross-section and high moderating efficiency.

- Semiconductors and Aerospace: High-purity graphite supports semiconductor manufacturing, solar cell production, and aerospace components, where thermal management and purity are paramount.

Do you need help identifying the best graphite block for your application? Try questions like: Which graphite block is best for battery manufacturing? What type of graphite is used in high-temperature reactors? How do graphite blocks improve chemical process efficiency?

Benefits of Graphite Blocks: Performance, Reliability, and Value

- Graphite blocks provide high mechanical strength, density, and thermal conductivity, ensuring reliable performance in demanding industrial environments.

- They deliver exceptional electrical conductivity, essential for electrodes, current collectors, and energy storage devices.

- Graphite’s refractory properties—high thermal shock resistance and low thermal expansion—reduce failure rates in furnace linings and casting molds.

- Outstanding machinability allows for custom block dimensions and complex geometries, supporting specialized manufacturing and research applications.

- Chemical stability and lightweight composition make graphite blocks ideal for corrosive or weight-sensitive environments, such as chemical processing or aerospace.

- Graphite blocks have a long service life, reducing downtime and maintenance costs in industrial operations.

- Consistent product quality and purity support critical applications in electronics, semiconductors, and advanced materials engineering.

Resistance to Hot Metals and Aggressive Environments

In aluminum smelting and other metal processing systems, premium graphite blocks are used for sidewalls and furnace linings. Their low porosity and high solubility resistance prevent hot metals from penetrating the block, leading to longer service life and improved system integrity. The robust nature of these blocks minimizes contamination, optimizes process efficiency, and ensures product consistency even under extreme thermal and chemical stress.

Thermal Resistance and Longevity

One of the leading causes of refractory block failure is thermal degradation. By selecting only high-quality carbon and graphite blocks, manufacturers can drastically prolong the lifespan of furnace linings and process equipment. Advanced filling materials, sealants, and manufacturing techniques further enhance the durability of graphite blocks, ensuring continuous operation in the most demanding metallurgical, chemical, and energy production applications.

Environmental and Economic Benefits

Graphite is sourced from both renewable and non-renewable resources, with recycling programs increasingly important for sustainable supply. The long lifespan and energy efficiency of graphite blocks contribute to lower operational costs and reduced environmental impact, supporting corporate sustainability goals and compliance with environmental regulations.

Choosing the Right Graphite Block Manufacturer: What to Consider

Purchasing graphite blocks requires careful evaluation of suppliers to ensure quality, reliability, and value. Important decision factors include raw material sourcing, manufacturing expertise, product certifications, and customer support. When comparing graphite block manufacturers, consider:

- Material Purity and Consistency: Does the manufacturer offer blocks with verified purity and consistent properties suitable for your application?

- Customization and Machining Capabilities: Can they provide custom sizes, shapes, or special finishes to meet your technical requirements?

- Technical Support and Collaboration: Is there responsive technical support for application engineering, troubleshooting, and process optimization?

- Certifications and Quality Assurance: Are products certified to relevant industry standards (e.g., ISO, ASTM, nuclear-grade)?

- Lead Times and Supply Chain Reliability: Does the supplier have a reputation for timely delivery and robust inventory management?

- Environmental Stewardship: Are sustainable sourcing and recycling practices in place to minimize environmental impact?

To streamline your supplier search, leverage our comprehensive directory of graphite block manufacturers. Each supplier profile highlights core competencies, areas of expertise, and unique capabilities—enabling you to compare offerings and select the best partner for your project. Our proprietary website previewer allows you to quickly evaluate business focus, and our easy-to-use RFQ form lets you request quotes from multiple manufacturers simultaneously.

Ready to take the next step? Request a quote or contact leading graphite block manufacturers today to ensure your project benefits from the highest quality materials and expert technical support.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services