Graphite is a material that is widely employed in many different types of industries. It is available in both natural and artificial forms. Natural graphite is a mineral that is mostly composed of carbon and is a semimetal. It is extracted from igneous and metamorphic rock, and its crystallinity varies greatly. Natural graphite is a superb conductor of heat and electricity because it is stable across a wide temperature range and has a melting point of 3650 °C (6602 °F). Read More…

At Weaver Industries we specialize in manufacturing machined graphite parts and products. Our goal is to ensure that our customers get the right tools for their applications. We are leaders in the industry for our graphite machining processes which include recycling and reclaiming machined electrodes. Custom molded urethane and high quality carbon graphite are only a few of our other...

At Amsted, we specialize in precision graphite machining, delivering advanced solutions that meet the exacting standards of modern industries. Our team brings together decades of expertise and state-of-the-art technology to produce high-performance graphite components with superior accuracy, consistency, and surface quality.

SGL Carbon Group is the world's largest manufacturer of carbon and graphite, a leading provider of graphite specialties and the only company in the world to master all related manufacturing processes. We serve many industries with graphite materials, system solutions and graphite design.

More Graphite Companies

The three material subclasses of amorphous, flake, and high crystalline natural graphite are further broken down. The most common applications for this material include refractories, batteries, expanded graphite, brake linings, foundry facings, and lubricants. Pitch and coke can be used to make synthetic graphite. Despite not being as crystalline as natural graphite, it frequently has a greater purity level. Generally speaking, synthetic graphite is less dense, more porous, and more electrically resistive. It is not appropriate for refractory applications due to its porosity level.

Materials That Comprise Graphite

Pure carbon is used to make graphite. Bonds can be formed between carbon atoms to produce a variety of structures. Two of the most well-known allotropes of carbon are diamond and graphite. Although each allotrope is composed of carbon, the varied arrangements of the carbon atoms give rise to significantly diverse physical qualities. For instance, graphite is far softer than a diamond on the Mohs scale.

Applications of Graphite

Due to the broad range of uses for graphite, manufacturers may reach a large audience with their goods. Graphite manufacturers may create silicon and carbon chemical compounds called alpha silicon carbide or beta silicon carbide. These substances function as non-oxide ceramic powders that are very sinterable. Customers can purchase them for a variety of purposes.

High-performance wear components, including seal rings and pump parts, are made from alpha SiC and used in abrasive and armor applications. Beta SiC is also utilized in toner for improved flowability and internal printer cleaning, in high-performance wear components, and nickel, chrome, aluminum, and other metals for strength.

Applications as Energy Materials

The market for energy materials is another one that graphite producers dominate. Graphite is a key component of many electrochemical systems, including primary alkaline batteries, ion-lithium batteries, lead acid batteries, rechargeable alkaline batteries, fuel cells, and many more.

Applications as Refractory Materials

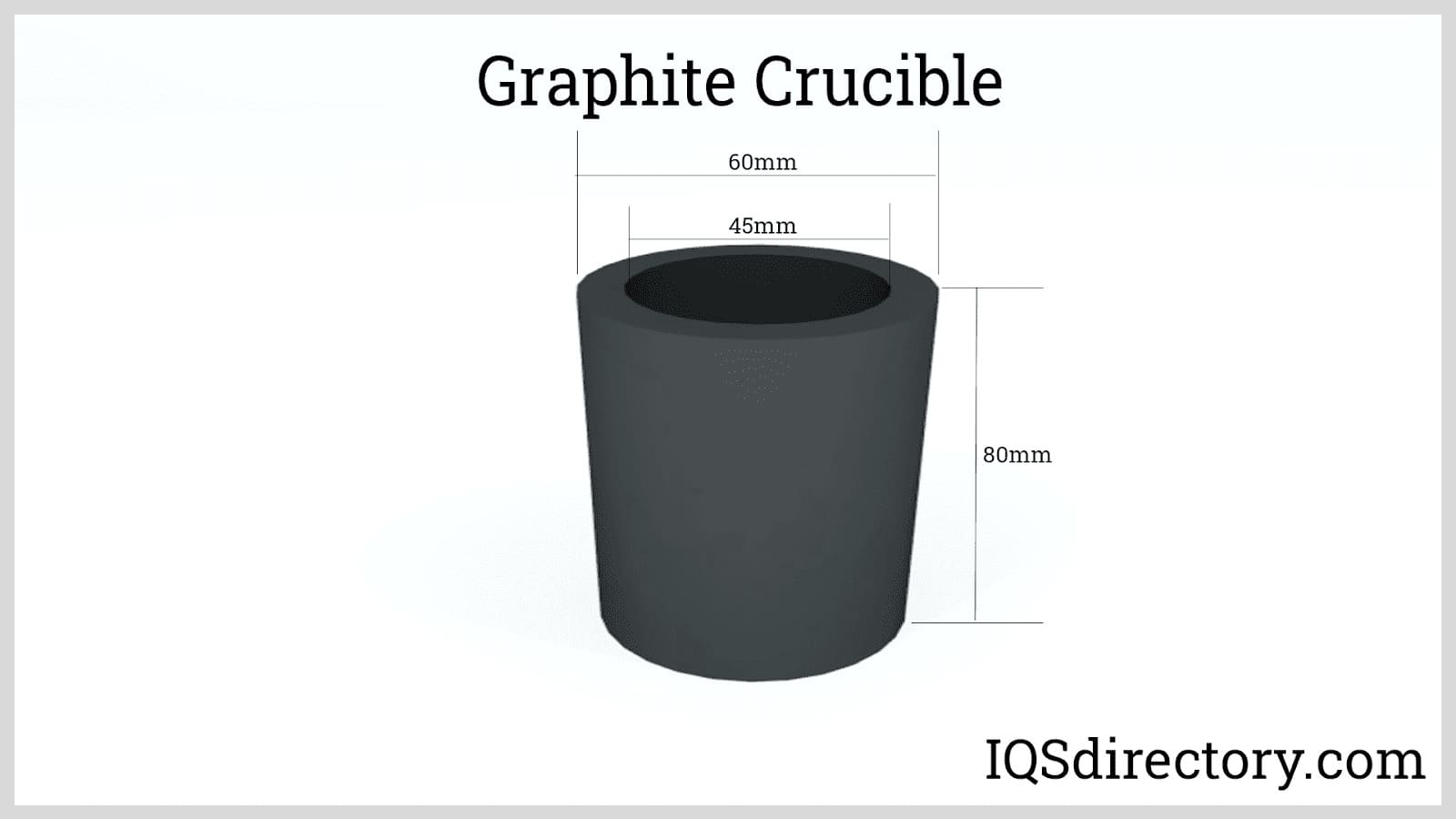

Graphite producers compete successfully in the refractory industry, where the graphite they sell is used to create kiln and blast furnace bricks. Additionally, it is used to make molds, ladles, and crucibles for holding molten metals. One of the most often utilized materials in producing refractories for the continuous casting of steel is graphite flake.

Applications in the Chemical Industry

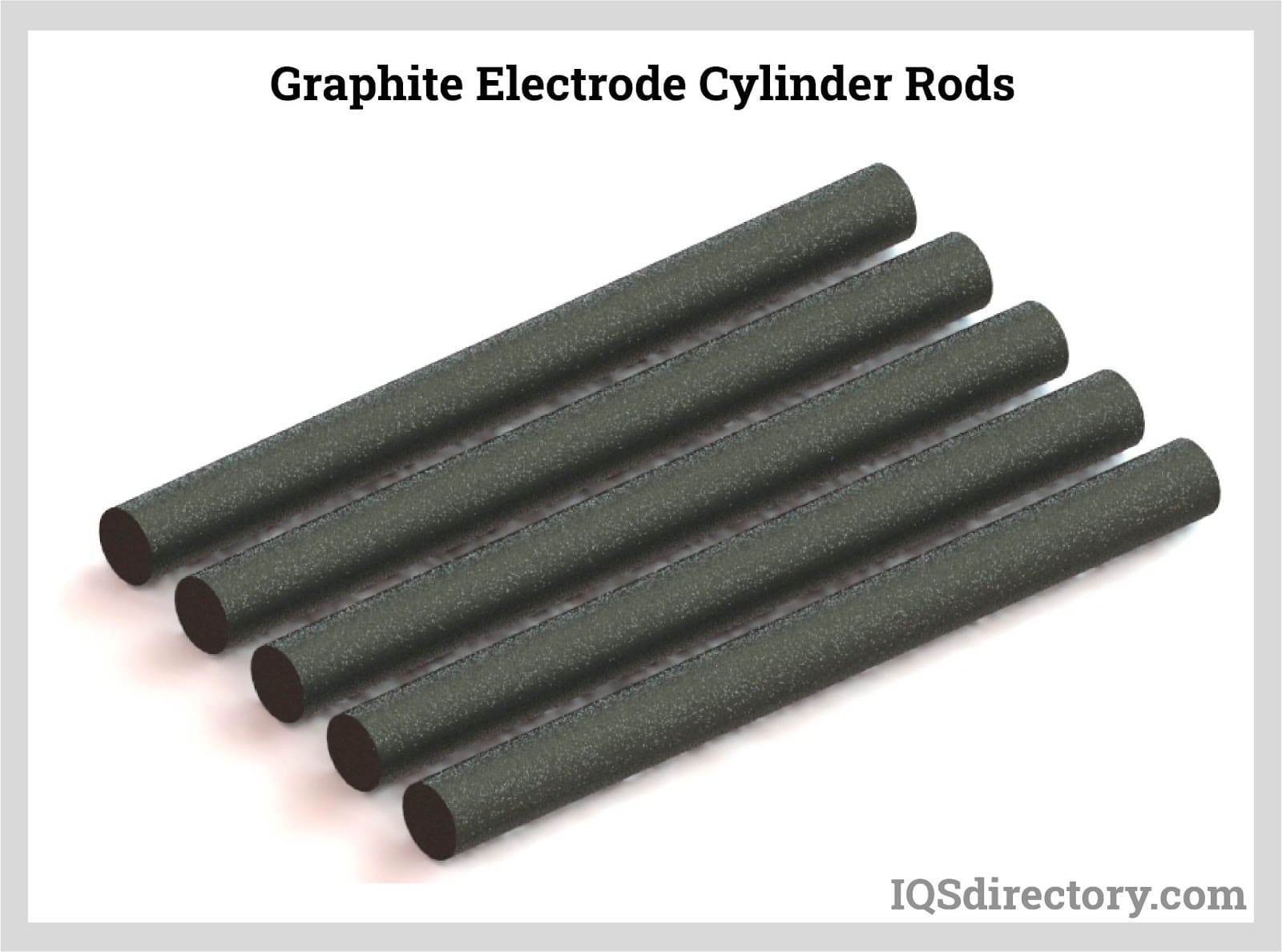

Given graphite's extraordinarily high melting point, graphite serves numerous applications within the chemical industry. Graphite is utilized in high-temperature operations like the arc furnace manufacture of calcium carbide and phosphorus. In some aquatic electrolytic processes, such as the creation of halogens like fluorine and chlorine, it is also utilized to carry electricity.

The nuclear industry benefits from high-purity electro graphite's low neutron absorption, strong thermal conductivity, and ability to sustain strength at high temperatures. It is extensively utilized in manufacturing moderator rods and reflector parts for nuclear reactors. Manufacturers of graphite have a long history in the mechanical and engineering fields.

Advantages of Manufacturing Graphite

Graphite can be produced synthetically or organically. It is possible to mine naturally occurring graphite resources in several nations, including China, Madagascar, Brazil, and Canada. Graphite is a mineral created by igneous and metamorphic physical processes. Heat transforms carbon-containing materials into synthetic graphite (including petrochemicals, pitch, coal, or acetylene).

The carbon atoms rearrange themselves into layers when superheated (to temperatures higher than 4000°C), forming graphite. It is widely acknowledged that synthetic graphite is purer than naturally occurring graphite. Other advantages of manufactured granite are listed below.

- It is easy to machine.

- Thermal stress doesn't affect it.

- The stability of the electrode geometry during electro-discharge machining is guaranteed by its low coefficient of thermal expansion, which is three times lower than copper.

- It is offered in big blocks.

- At 3,400°C, it transitions immediately from the solid to the gaseous state without melting, reducing wear.

- Since its density is five times lower than copper, the resulting electrodes are lighter.

- It offers a higher metal removal rate with less wear than copper.

- Its distinctive feature is that as peak current rises, the wear ratio tends to fall.

Choosing the Correct Graphite Manufacturers

To ensure you have the most productive outcome when purchasing graphite from a graphite manufacturer, it is important to compare several companies using our directory of graphite manufacturers. Each graphite manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each graphite manufacturer company website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple graphite manufacturers with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services