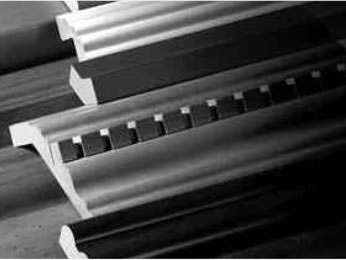

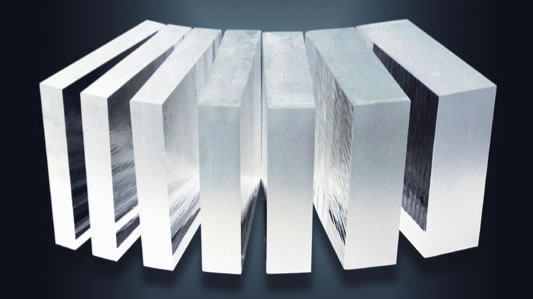

Graphite is a very beneficial material due to its strength, hardness, corrosion resistance, dry lubrication and self lubrication. In order to machine it heavy duty processes are necessary to make it into the various products that are needed in the graphite industry. One of these methods is electrical discharge machining. This is a process used to cut, drill, etch and machine various metal parts. It works especially well with metals that would be difficult to process with traditional methods. The conductive properties and temperature resistance that this graphite possesses makes it ideal for this process. By producing the parts through graphite EDM processes, the metals can be formed without burrs, a common issue that arises with traditional cutting methods.

One issue with EDM is that the electrodes need to be replaced from time to time, and this can be an expensive replacement. This is an advantage of choosing graphite for the electrode. Graphite electrodes tend to last longer than other options. In addition it is able to remove metal at a faster rate. The graphite electrodes carry an electric current to tool the shape desired into the materials. The easy machining ability of the material makes it simple to form the metal without burning, chemically changing or melting the material. Another benefit it is able to provide is that it is relatively inexpensive, further it can be redressed multiple times making it even more cost effective.

When it comes to EDM graphite there are five main physical properties that are measured. These are particle size, flexural strength, hardness, density and electrical resistance. These different factors can lead to different benefits and attributes when machining. For example, smaller particles will result in a smoother finished product, but larger particles will be able to remove more metal and a higher rate.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services